The contract between Khouzestan steel complex and German Corporartion, Lurgi Has been Made at 1974.

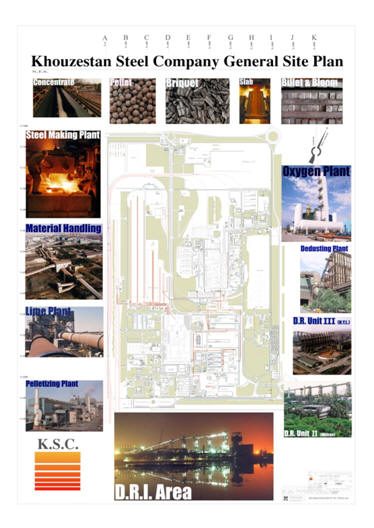

The Complex Has 3 active Midrex® Direct Reduction Modules, Producing 1,800,000 tpy Sponge Iron.

Contractors and Consultants:

- Foster Veiler Co. – Tehran Jonoob Co.

- Mashin Sazie Pars Co.

- Nader Construction Co.

- Tadbir Sanat Co.

- Kaiser Co.- Tadbir Sanat Co.

After Islamic Revolution in 1978 Most of These Corporation (Specially Lurgi, Kaiser and Foster Veiler) Have Abandoned The Site.

Poolad’s Liabality for Auditing current Situation

- Coordination between former Contractors and Consultants in order to Resolve Legal Disputes.

- Peparing the Main Tender For Second Pelletizing Plant Consisting of Proposed time schedule, Scope of Work and Making Contraction with proper Contractors

- Preparing The General Conditions of Contract

- Preparing The Specific Conditions of Contract

- Preparing Contractor’s Obligations

- Audition of Current Situation and Design for Repairing and Revamping Sections Damaged During Imposed War.